Albert Manero wins Fulbright Fellowship to conduct doctoral research at DLR in Cologne, Germany

Audios

Measurements for stress sensing of composites using tailored piezospectroscopic coatings

Read our paper in AIP Advances

Abstract:

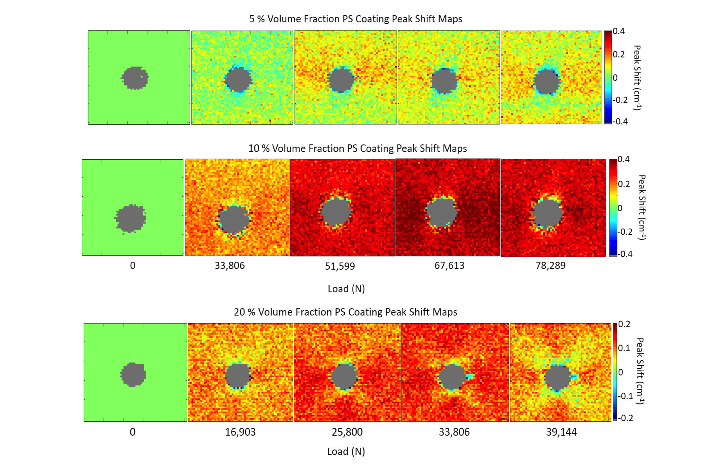

Chromium-doped alpha-alumina is naturally photo-luminescent with spectral properties that are characterized by R-lines with two distinct peaks known as R1 and R2. When the material is subjected to stress, shifts in the R-lines occur, which is known as the piezospectroscopic (PS) effect. Recent work has shown that improved sensitivity of the technique can be achieved through a configuration of nanoparticles within a polymer matrix, which can be applied to a structure as a stress-sensing coating. This study demonstrates the capability of PS coatings in mechanical tests and investigates the effect of nanoparticle volume fraction on sensing performance. Here, measurements of spectral shifts that capture variation in stress of the coating during mechanical testing and in the region of substrate damage showed that stress contours are more noticeable on a soft laminate than hard laminate. It was found that the 20 % volume fraction PS coating showed the most distinct features of all the coatings tested with the highest signal-to-noise ratio and volume fraction of alpha-alumina. Post failure assessment of the PS coatings verified that the coatings were intact and peak shifts observed during mechanical testing were due to the stress in the substrate. The results suggest the ability to design and tailor the “sensing” capability of these nanoparticles and correlate the measured stress variations with the presence of stress and damage in underlying structures. This study is relevant to nondestructive evaluation in the aerospace industry, where monitoring signs of damage is of significance for testing of new materials, quality control in manufacturing and inspections during maintenance.

To view more posts like this, check out the Highlights page here.

You can also hear about Remelisa’s paper in the All Audio Posts page here.

Stress and structural damage sensing piezospectroscopic coatings validated with digital image correlation

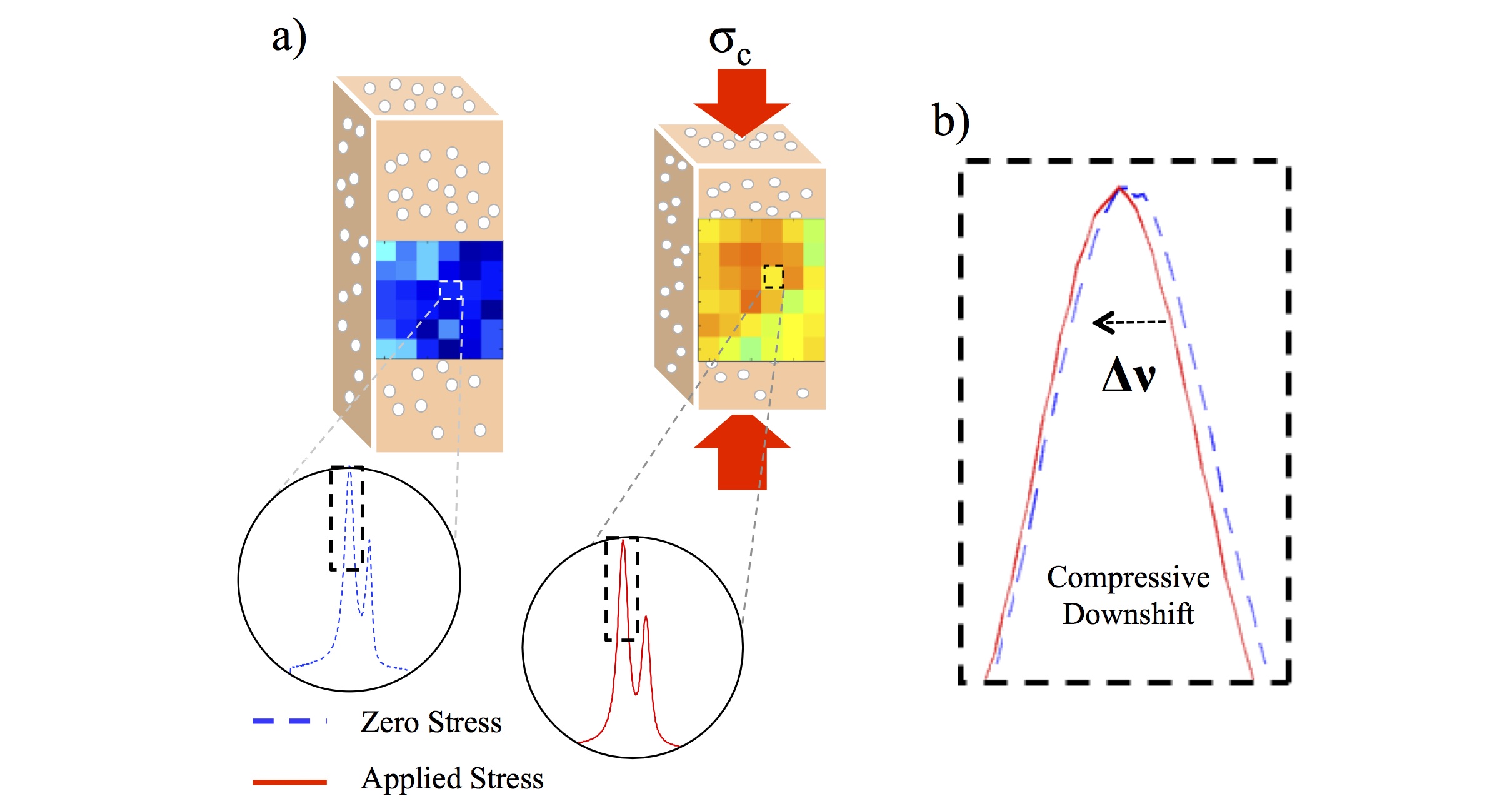

The piezospectroscopic effect, relating a material’s stress state and spectral signature, has recently demonstrated tailorable sensitivity when the photo-luminescent alpha alumina is distributed in nanoparticulate form within a matrix. Here, the stress- sensing behavior of an alumina-epoxy nanoparticle coating, applied to a compos- ite substrate in an open hole tension configuration, is validated with the biaxial strain field concurrently determined through digital image correlation. The coating achieved early detection of composite failure initiation at 77% failure load, and subsequently tracked stress distribution in the immediate vicinity of the crack as it progressed, demonstrating non-invasive stress and damage detection with multi-scale spatial resolution.

Portable Piezospectroscopy system: non-contact in-situ stress sensing through high resolution photo-luminescent mapping

Read our paper in the Journal of Instrumentation

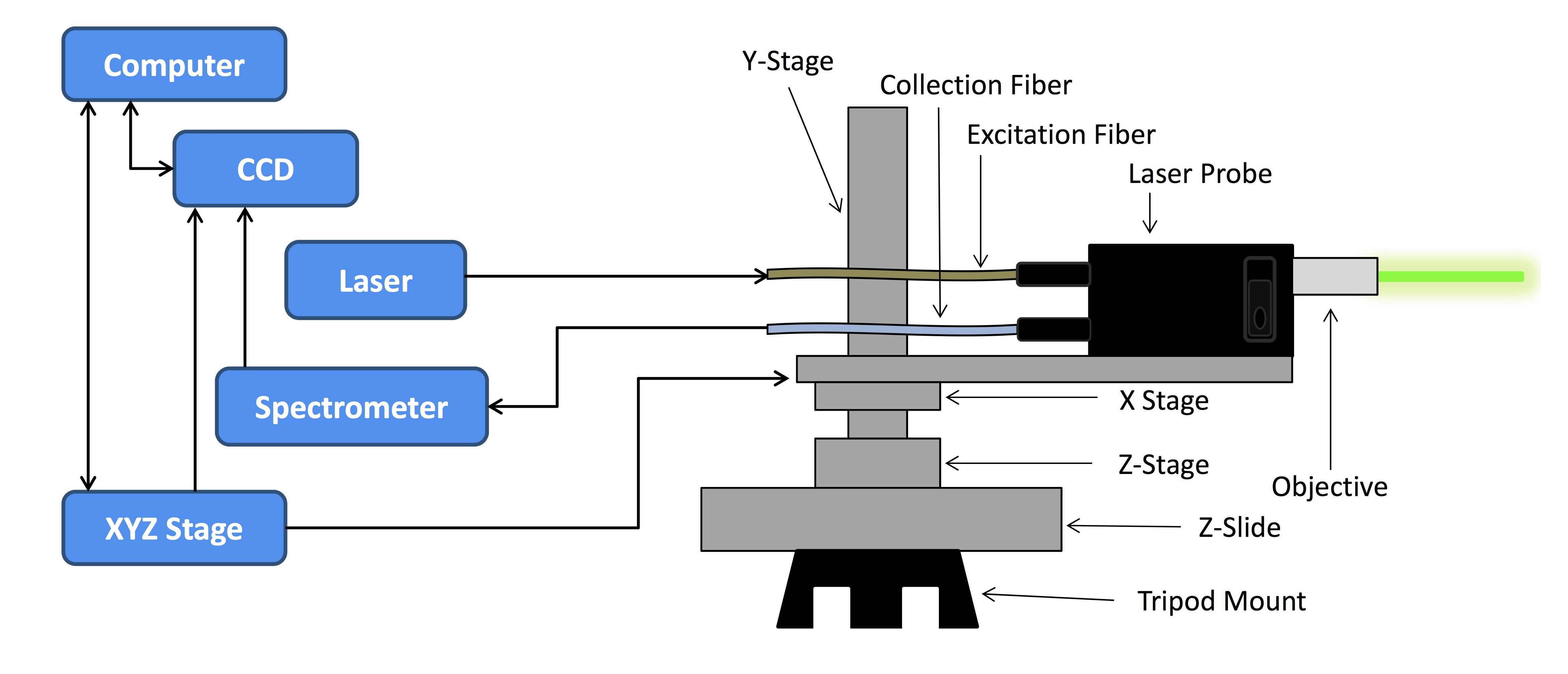

Through the piezospectroscopic effect, certain photo-luminescent materials, once excited with a laser, produce spectral emissions which are sensitive to the stress or strain that the material experiences. A system that utilizes the piezospectroscopic effect for non-contact stress detection over a material’s surface can capture important information on the evolution of mechanical response under various conditions. Therefore, the components necessary for piezospectroscopic mapping and analysis have now been integrated into a versatile and transportable system that can be used with photo-luminescent materials in any load frame or on a variety of structures. This system combines compact hardware components such as a portable laser source, fiber optics, spectrograph, charge-coupled device (CCD), and an X-Y-Z stage (with focusing capabilities) with a series of data analysis algorithms capable of analyzing and outputting high resolution photo-luminescent (PL) maps on-site. Through a proof of concept experiment using a compressed polycrystalline alumina sample with sharp machined corners, this system successfully captured high resolution PL maps with a step size of 28.86 μm/pixel and located high stress concentrations in critical areas, which correlated closely with the results of a finite element model. This work represents an important step in advancing the portability of piezospectroscopy for in-situ and non-contact stress detection. The instrumentation developed here has strong implications for the future of non-destructive evaluation and non-invasive structural health monitoring.

Multiscale mechanics to determine nanocomposite elastic properties with piezospectroscopy

Read our paper in Acta Materialia

Abstract:

The piezospectroscopic (PS) properties of chromium-doped alumina allow for embedded inclusion mechanics to be revisited with unique experimental setups that probe the particles’ state of stress when the composite is under applied load. These experimental investigations of particle mechanics will be compared to the Eshelby theory and a derivative theory. This work discovers that simple nanoparticle load transfer theories are adequate for predicting PS properties in the low to intermediate volume fraction range (⩽20%). By applying the multiscale mechanics to a PS response, the inverse problem was demonstrated to reveal the elastic modulus of the composite. The implications for this technique are damage monitoring through observation of reduced mechanical properties in addition to a method to assist with engineering nanomaterials.

Piezospectroscopic Measurements Capturing the Evolution of Plasma Spray-Coating Stresses with Substrate Loads

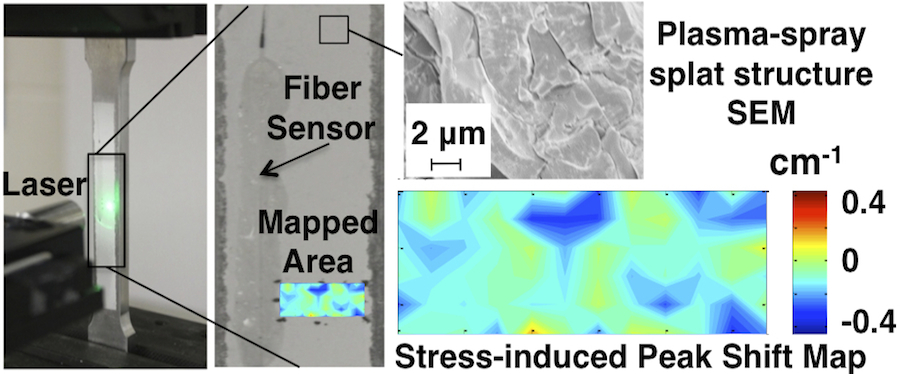

Our paper in Applied Materials & Interfaces highlights the evolution of stress within APS coatings under increasing substrate loads captured using piezospectroscopy.

Abstract

Plasma-spray coatings have a unique microstructure composed of various types of microcracks and weakly bonded interfaces which dictate their nonlinear mechanical properties. The intrinsic photo-luminescence (PL) characteristics of alpha-alumina (α-Al2O3) within these coatings offer a diagnostic functionality, enabling these properties to be probed experimentally at the microscale, under substrate loading. The piezospectroscopic (PS) measurements from the coatings are capable of revealing microstructural stress at high spatial resolution. Here, for the first time, the evolution of stresses within air plasma spray (APS) coatings under increasing substrate loads were captured using piezospectroscopy. With mechanical cycling of the substrate, the PS properties revealed anelastic and inelastic behavior and a relaxation of residual tensile stress within the APS coatings. With decreasing substrate thickness, the coating was observed to sustain more stress, as the substrate’s influence on the mechanical behavior decreased. The findings provide an insight into the microstructural response that can serve as the basis for model validation and subsequently drive the design process for these coatings.