Gregory Freihofer wins 2nd place at the SAMPE CAMX student paper competition

Dr. Bartsch and I discussing my work.

Hello all,

Thanks to winning a Fulbright student grant, I’ve been in Cologne, Germany since mid-September, conducting research for my masters’ thesis at the German Aerospace Center (DLR). I’m studying thermal barrier coatings (TBCs), which are coating systems used to protect the components in the hot section of gas turbine engines used for aircraft propulsion and power generation. I’m comparing two methods of depositing the ceramic top coat. Electron-beam physical vapor deposition (EB-PVD) is the industry standard method for producing the high-quality coatings used on the most critical hot-section components of aero-engines. The process involves vaporizing a solid ceramic target in a high vacuum, and the ceramic vapor condenses onto the part, which gives it a characteristic microstructure that is “strain tolerant” – less likely to crack with the repeated expansion and contraction associated with thermal cycles. Because the vapor must diffuse onto the coating, the process is slow, and the high vacuum requirement makes the process more difficult and expensive. The second process is plasma-spray physical vapor deposition (PS-PVD), which is a newer process that is faster, cheaper, and promises greater flexibility than EB-PVD. In this process, ceramic powder is injected into a plasma plume, where it is either melted or vaporized, depending on the process parameters. Because the plasma plume carries the ceramic to the part at high speed, the coating rate is much higher, and there is some non-line-of-sight capability, which will enable more complex part geometries or even multiple parts to be coated at once. Changing the process parameters also controls the resulting microstructure, which is relevant to applications beyond TBCs in engines – for example, gas-sending membranes or ion transport layers in fuel cells. Before PS-PVD TBCs can be adopted commercially, their properties and response to service conditions must be compared to EB-PVD TBCs. My work compares samples of both times, which have received varying amounts of thermal cycling to simulate low-, mid-, and high-lifetime coatings.

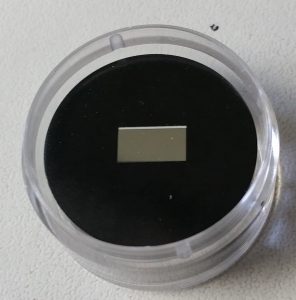

Embedded cross section of my dummy EB-PVD sample. That thin white layer is the TBC. The temperature drop across it can be as great as 200 °C (nearly 400 °F)!

I’ve been busy analyzing spectroscopy data that I’ve collected on my samples. Photoluminescent piezospectroscopy (PLPS) and Raman spectroscopy are non-destructive optical methods that provide information on the residual stress state of the coatings, which indicates remaining lifetime. Even more exciting, I’m planning my further testing with my mentor, Dr. Bartsch, here at DLR.

I’ll be imaging my samples with scanning electron microscopy and energy-dispersive x-ray spectroscopy. These techniques are time-consuming, expensive, and highly dependent on good quality sample preparation, so it’s critical to plan carefully and know what you’re looking for before you start. I’ll be using these techniques to support and explain my conclusions from my spectroscopy results. Dr. Bartsch has kindly provided me with some “dummy” samples similar to my own, for me to train and practice on. You don’t want to do a technique for the first time on your valuable samples, especially when it’s destructive!

I started by cutting a small piece from one of the dummy samples, embedding it in conductive mounting material, and polishing the cross section. The quality of surface finish is extremely important for good images. I took a few optical microscope images of the dummy, to check the surface finish and practice using the microscope. More surface preparation will be needed before I can image it with the electron microscope.

DLR is home to experts in the world of TBCs, and it’s a privilege to get their advice and feedback on my work. It’s a little surreal to have scientific conversations with some of the authors of papers I’ve read! Dr. Bartsch has a lot of expertise to share, not only on TBCs but also on the sample preparation and testing I’ll be doing. (Bonus: she’s the nicest lady you’ll ever meet.) At DLR, I also have access to a caliber of equipment that I wouldn’t have back at UCF, along with expert technicians and scientists to help me get the most out of it. And of course, the experience of living in another country and experiencing another culture is irreplaceable.

More updates later,

Lin Rossmann