Ashley and Greg performed summer research at Boeing Seattle

Category Archives Highlights

Quantifying thermal barrier coating delamination through luminescence modeling

Read our paper in Surface and Coatings Technology

Abstract:

Thermal barrier coatings (TBCs) are widely used in the hot sections of gas turbine systems as they are remarkably efficient in insulating the underlying superalloys, leading to higher operating temperatures and therefore enhancing the performance of the engines. However, this benefit is only possible if the integrity of the TBC under aggressive thermo-mechanical environments is ensured. Delamination is a common but hard to detect failure mode. We present, in this work, supported by experimentation, the implementation of a modeling approach applying the Kubelka-Munk theory to provide numerical quantification of luminescence contrast and intensity due to top coat delamination in TBCs. The method relies on the drastic change in reflectivity when a delamination forms, exploiting it for high-contrast luminescence mapping. Two distinct TBC configurations containing an erbium-doped yttria-stabilized zirconia (YSZ:Er3+) layer for delamination sensing were used to validate this model. A delamination zone induced by Rockwell indentation was successfully tracked by measuring an increase of the intensity of the erbium emission line at 562 nm. Luminescence-based methods for delamination detection can provide a revolutionary non-invasive technique, with potential for both off-line and on-line engine monitoring.

To view more posts like this, check out the Highlights page here.

You can also hear about Quentin’s paper in the All Audio Posts page here.

High-energy X-ray phase analysis of CMAS-infiltrated 7YSZ thermal barrier coatings: Effect of time and temperature

Read our paper in Journal of Materials Research

Abstract:

Calcium–magnesium–alumino-silicate (CMAS) particulates enter the aero-engine in a sandy environment, melt and infiltrate into 7 wt% yttria-stabilized zirconia (7YSZ) thermal barrier coatings (TBCs), reducing their lifetime. This leads to chemical degradation in 7YSZ accompanied by tetragonal to monoclinic phase transformation upon cooling. In this work, electron-beam physical vapor deposition coatings were infiltrated with a synthetic CMAS. Synchrotron X-ray diffraction measurements show that CMAS infiltration at 1250 °C has about 43% higher monoclinic phase volume fraction (PVF) at the coating surface compared to 1225 °C and remains consistently higher throughout the coating depth. Additionally, the increase in annealing time from 1 to 10 h results in a 31% higher monoclinic phase at the surface. Scanning electron microscopy revealed the presence of globular monoclinic phases corresponding spatially with the above findings. These results resolve the impact of time and temperature on CMAS infiltration kinetics which is important for mitigation.

To view more posts like this, check out the Highlights page here.

You can also hear about Zachary’s paper in the All Audio Posts page here.

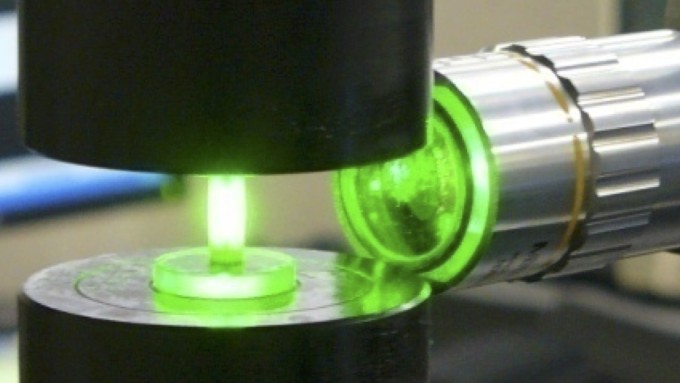

Phosphor thermometry instrumentation for synchronized acquisition of luminescence lifetime decay and intensity on thermal barrier coatings

Read our paper in Measurement Science and Technology

Abstract:

Thermal barrier coatings (TBCs) are used to protect turbine components from extreme environments and to allow for the turbine system to operate at temperatures beyond the melting point of the underlying superalloy blade. Existing in situ temperature measurement methods for high temperature evaluation have inherent uncertainties that impose important safety margins. Improving the accuracy of temperature measurements on the materials in operating conditions is key for more reliable lifetime predictions and to increase turbine system efficiencies. For this objective, phosphor thermometry shows great potential for non-invasive high temperature measurements on luminescent coatings. In this work, a phosphor thermometry instrument has been developed to collect two emission peaks simultaneously of an erbium and europium co-doped yttria-stabilized zirconia TBC, enabling an extended temperature range and high precision of the in situ temperature assessment. The luminescence lifetime decays and the intensity variations of both dopants were captured by the instrument, testing its high sensitivity and extended temperature range capabilities for accurate measurements, up to operating temperatures for turbine engines. The results open the way for the applicability of portable phosphor thermometry instrumentation to perform effective temperature monitoring on turbine engine materials and support the advancement of innovative sensing coatings.

To view more posts like this, check out the Highlights page here.

You can also hear about Quentin’s paper in the All Audio Posts page here.

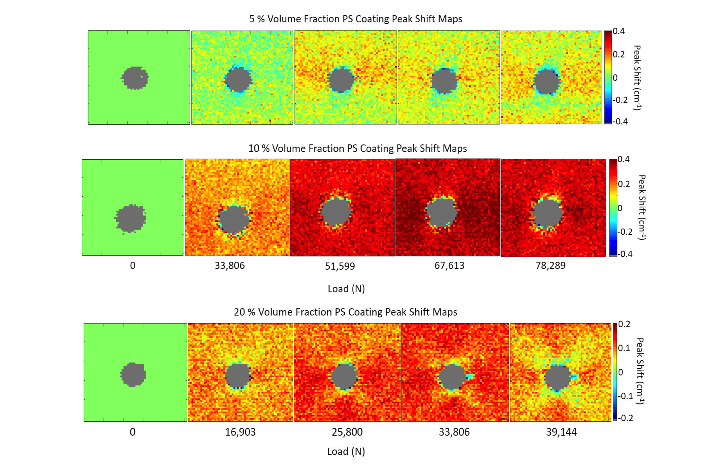

Measurements for stress sensing of composites using tailored piezospectroscopic coatings

Read our paper in AIP Advances

Abstract:

Chromium-doped alpha-alumina is naturally photo-luminescent with spectral properties that are characterized by R-lines with two distinct peaks known as R1 and R2. When the material is subjected to stress, shifts in the R-lines occur, which is known as the piezospectroscopic (PS) effect. Recent work has shown that improved sensitivity of the technique can be achieved through a configuration of nanoparticles within a polymer matrix, which can be applied to a structure as a stress-sensing coating. This study demonstrates the capability of PS coatings in mechanical tests and investigates the effect of nanoparticle volume fraction on sensing performance. Here, measurements of spectral shifts that capture variation in stress of the coating during mechanical testing and in the region of substrate damage showed that stress contours are more noticeable on a soft laminate than hard laminate. It was found that the 20 % volume fraction PS coating showed the most distinct features of all the coatings tested with the highest signal-to-noise ratio and volume fraction of alpha-alumina. Post failure assessment of the PS coatings verified that the coatings were intact and peak shifts observed during mechanical testing were due to the stress in the substrate. The results suggest the ability to design and tailor the “sensing” capability of these nanoparticles and correlate the measured stress variations with the presence of stress and damage in underlying structures. This study is relevant to nondestructive evaluation in the aerospace industry, where monitoring signs of damage is of significance for testing of new materials, quality control in manufacturing and inspections during maintenance.

To view more posts like this, check out the Highlights page here.

You can also hear about Remelisa’s paper in the All Audio Posts page here.

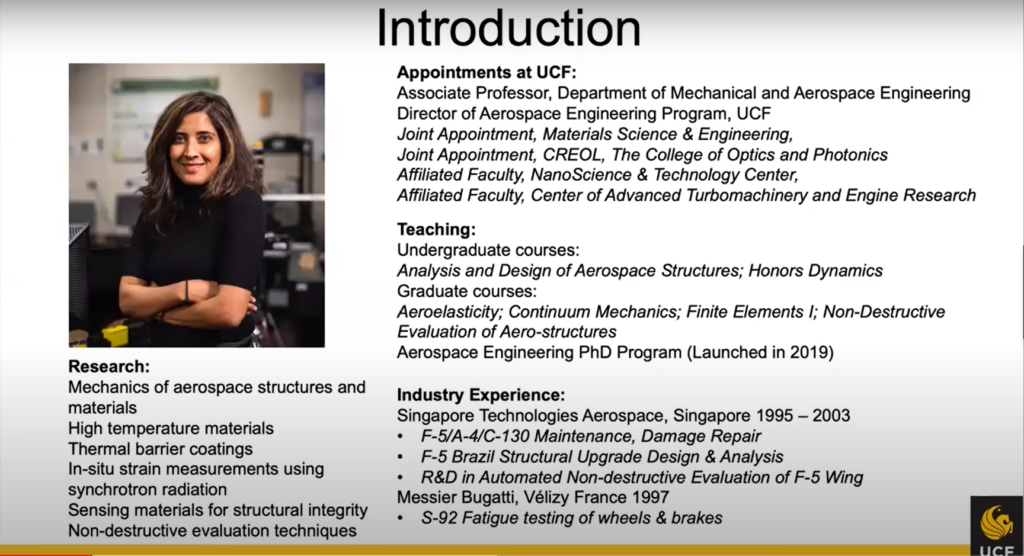

Raghavan Research Group Introduction

As part of UCF College of Engineering and Computer Science Virtual Faculty Research Talks, Dr Raghavan gives a brief introduction to the lab. She explains our motivations, various projects such as high temperature coatings, and where RRG is headed in the future.

Click here to watch the video.

Modeling luminescence behavior for phosphor thermometry applied to doped thermal barrier coating configurations

Read our paper in Applied Optics

Abstract:

Phosphor thermometry is a promising non-destructive method for accurate temperature measurement using phosphor elements that emit temperature-dependent luminescence. The method relies on the intensity and decay of luminescence arising from the phosphor elements upon excitation by an incident laser. In this work, the classical Kubelka–Munk model has been utilized and modified to model the luminescence emitted from phosphor elements that are added into thermal barrier coatings (TBCs) to enable temperature sensing using phosphor thermometry. The collectible luminescence and its time-decay behavior emerging from a tailorable multilayer TBC configuration have been predicted for different rare-earth dopants: Dy, Er, and Sm within an yttria-stabilized zirconia (YSZ) host, and with an operational gradient of temperature acting through its depth. The configurations have been designed by varying the position and thickness of the doped layer into the coating. The decay constant of the collectible luminescence has been used to determine the position in the coating from where the luminescence decay is the same as the decay of the collectible signal. This subsurface position indicates the location at which the temperature measurement is performed using phosphor thermometry under realistic operating conditions. It has been determined that YSZ:Dy provides the highest intensity of the collectible luminescence among the three dopant materials. In the TBC configuration with a fully doped coating, using YSZ:Er as a sensor enables temperature measurement from a more in-depth position in the coating. It has been shown that this position can be tailored by adjusting the geometrical configuration of the TBCs, varying the position and thickness of the doped layer. Due to the sensitivity of the dopants to temperature, the decay behavior of the emerging luminescence is demonstrated to change for different TBC configurations. The model can be used in screening the dopants to design multilayered TBCs for their suitability in temperature sensing by phosphor thermometry.

To view more posts like this, check out the Highlights page here.

You can also hear about Quentin’s paper in the All Audio Posts page here.

Stress and structural damage sensing piezospectroscopic coatings validated with digital image correlation

The piezospectroscopic effect, relating a material’s stress state and spectral signature, has recently demonstrated tailorable sensitivity when the photo-luminescent alpha alumina is distributed in nanoparticulate form within a matrix. Here, the stress- sensing behavior of an alumina-epoxy nanoparticle coating, applied to a compos- ite substrate in an open hole tension configuration, is validated with the biaxial strain field concurrently determined through digital image correlation. The coating achieved early detection of composite failure initiation at 77% failure load, and subsequently tracked stress distribution in the immediate vicinity of the crack as it progressed, demonstrating non-invasive stress and damage detection with multi-scale spatial resolution.

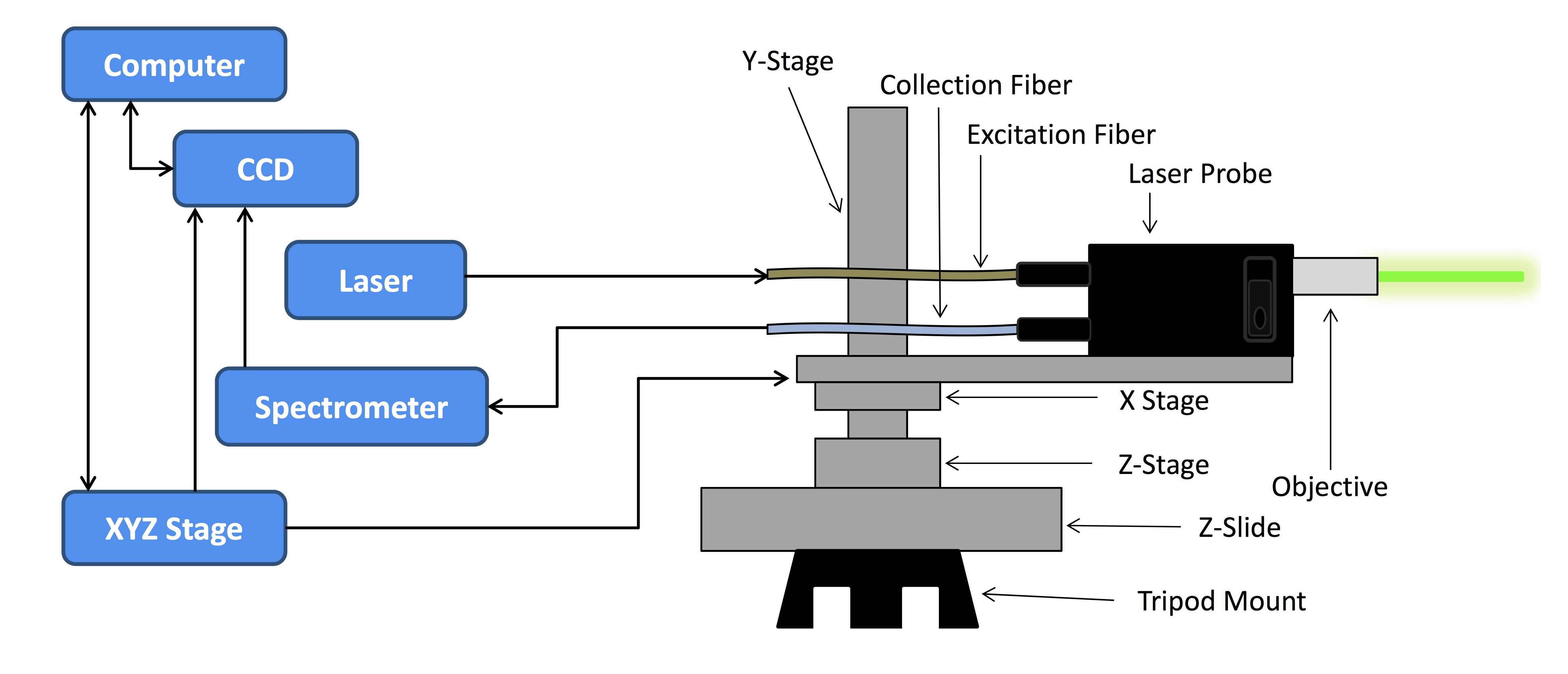

Portable Piezospectroscopy system: non-contact in-situ stress sensing through high resolution photo-luminescent mapping

Read our paper in the Journal of Instrumentation

Through the piezospectroscopic effect, certain photo-luminescent materials, once excited with a laser, produce spectral emissions which are sensitive to the stress or strain that the material experiences. A system that utilizes the piezospectroscopic effect for non-contact stress detection over a material’s surface can capture important information on the evolution of mechanical response under various conditions. Therefore, the components necessary for piezospectroscopic mapping and analysis have now been integrated into a versatile and transportable system that can be used with photo-luminescent materials in any load frame or on a variety of structures. This system combines compact hardware components such as a portable laser source, fiber optics, spectrograph, charge-coupled device (CCD), and an X-Y-Z stage (with focusing capabilities) with a series of data analysis algorithms capable of analyzing and outputting high resolution photo-luminescent (PL) maps on-site. Through a proof of concept experiment using a compressed polycrystalline alumina sample with sharp machined corners, this system successfully captured high resolution PL maps with a step size of 28.86 μm/pixel and located high stress concentrations in critical areas, which correlated closely with the results of a finite element model. This work represents an important step in advancing the portability of piezospectroscopy for in-situ and non-contact stress detection. The instrumentation developed here has strong implications for the future of non-destructive evaluation and non-invasive structural health monitoring.

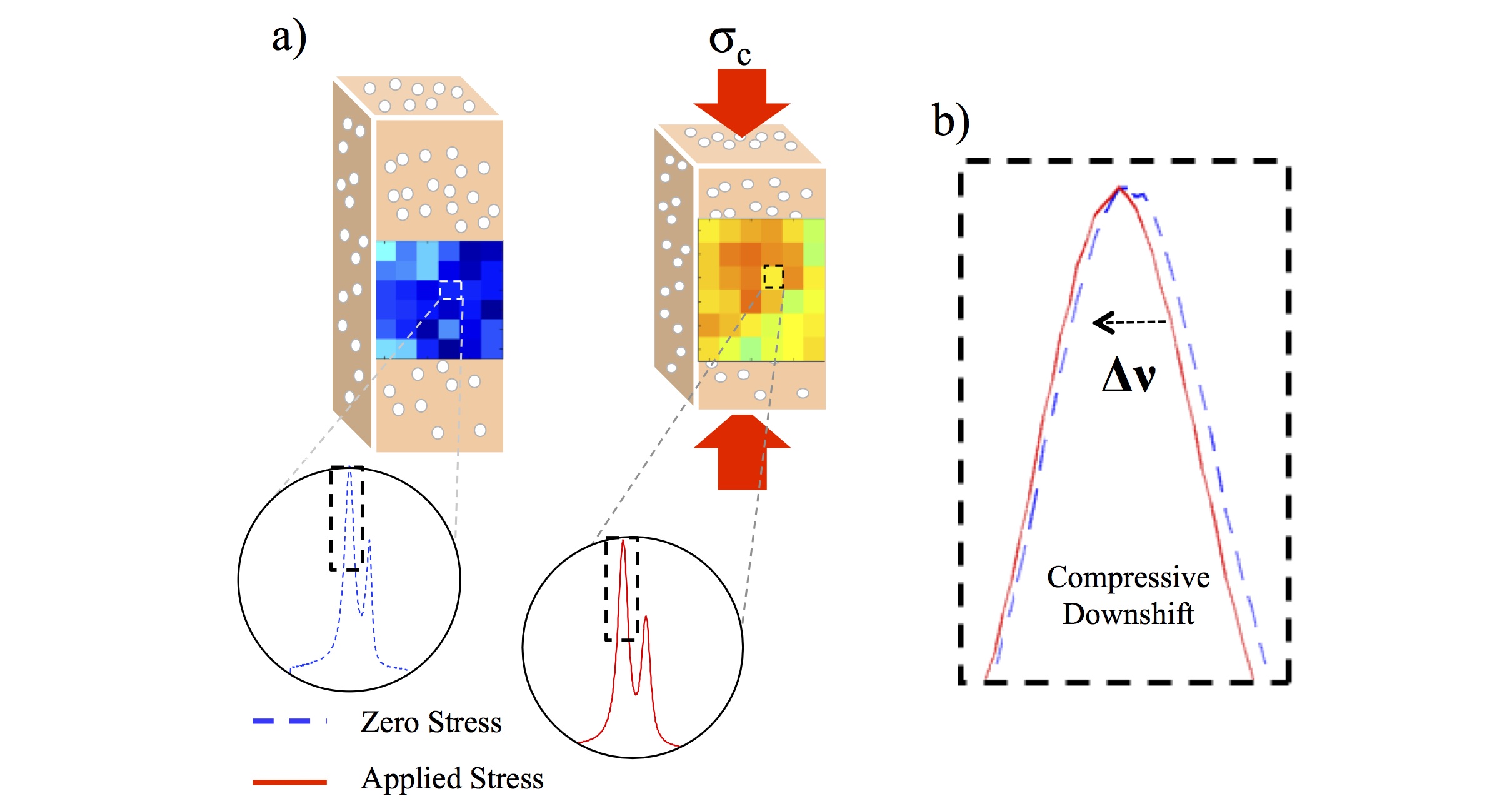

Multiscale mechanics to determine nanocomposite elastic properties with piezospectroscopy

Read our paper in Acta Materialia

Abstract:

The piezospectroscopic (PS) properties of chromium-doped alumina allow for embedded inclusion mechanics to be revisited with unique experimental setups that probe the particles’ state of stress when the composite is under applied load. These experimental investigations of particle mechanics will be compared to the Eshelby theory and a derivative theory. This work discovers that simple nanoparticle load transfer theories are adequate for predicting PS properties in the low to intermediate volume fraction range (⩽20%). By applying the multiscale mechanics to a PS response, the inverse problem was demonstrated to reveal the elastic modulus of the composite. The implications for this technique are damage monitoring through observation of reduced mechanical properties in addition to a method to assist with engineering nanomaterials.

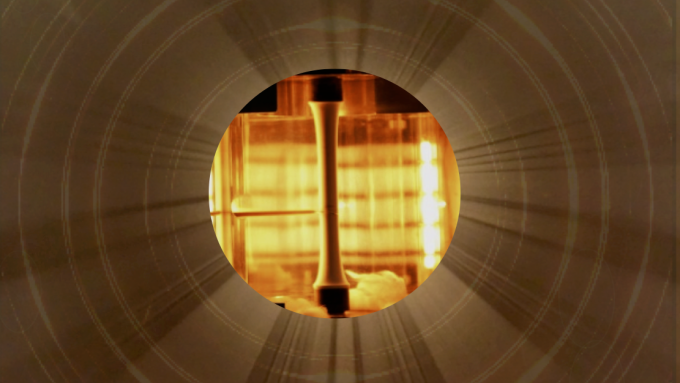

Capturing High Temperature Coating Strains under Extreme Engine Environments

Read our Nature Communications article

UCF today highlights our work.

Our work and international collaboration was featured on the Ceramic-tech-today

Abstract

The mechanical behaviour of thermal barrier coatings in operation holds the key to understanding durability of jet engine turbine blades. Here we report the results from experiments that monitor strains in the layers of a coating subjected to thermal gradients and mechanical loads representing extreme engine environments. Hollow cylindrical specimens, with electron beam physical vapour deposited coatings, were tested with internal cooling and external heating under various controlled conditions. High-energy synchrotron X-ray measurements captured the in situstrain response through the depth of each layer, revealing the link between these conditions and the evolution of local strains. Results of this study demonstrate that variations in these conditions create corresponding trends in depth-resolved strains with the largest effects displayed at or near the interface with the bond coat. With larger temperature drops across the coating, significant strain gradients are seen, which can contribute to failure modes occurring within the layer adjacent to the interface.

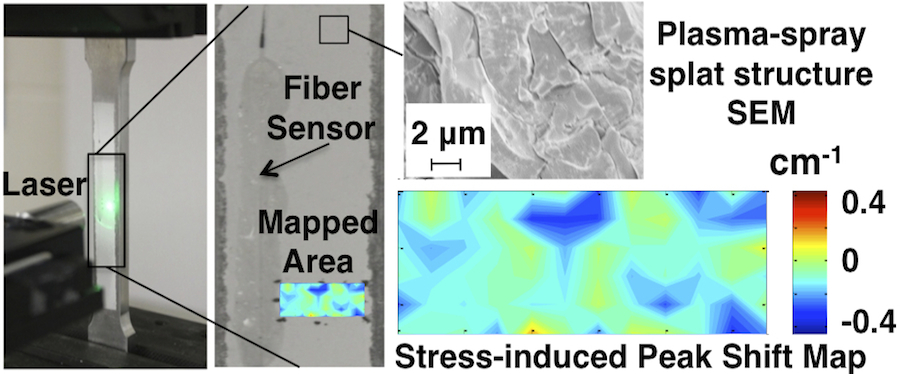

Piezospectroscopic Measurements Capturing the Evolution of Plasma Spray-Coating Stresses with Substrate Loads

Our paper in Applied Materials & Interfaces highlights the evolution of stress within APS coatings under increasing substrate loads captured using piezospectroscopy.

Abstract

Plasma-spray coatings have a unique microstructure composed of various types of microcracks and weakly bonded interfaces which dictate their nonlinear mechanical properties. The intrinsic photo-luminescence (PL) characteristics of alpha-alumina (α-Al2O3) within these coatings offer a diagnostic functionality, enabling these properties to be probed experimentally at the microscale, under substrate loading. The piezospectroscopic (PS) measurements from the coatings are capable of revealing microstructural stress at high spatial resolution. Here, for the first time, the evolution of stresses within air plasma spray (APS) coatings under increasing substrate loads were captured using piezospectroscopy. With mechanical cycling of the substrate, the PS properties revealed anelastic and inelastic behavior and a relaxation of residual tensile stress within the APS coatings. With decreasing substrate thickness, the coating was observed to sustain more stress, as the substrate’s influence on the mechanical behavior decreased. The findings provide an insight into the microstructural response that can serve as the basis for model validation and subsequently drive the design process for these coatings.

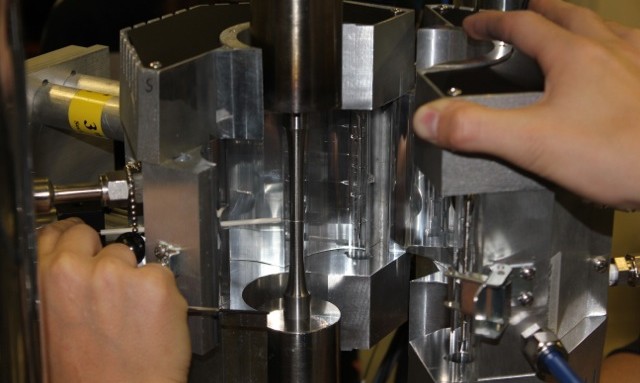

Synchrotron X-ray measurement techniques for cylindrical samples under thermal gradients

This study displays the ability to monitor in situ, the response of the internal layers within a layered coating, while implementing a thermal gradient across the thickness of the coated sample. The thermal setup maintained coating surface temperatures in the range of operating conditions, while monitoring the substrate cooling, for a controlled thermal gradient. Read our paper here.

Abstract

Measurement techniques to obtain accurate in situ synchrotron strain measurements of thermal barrier coating systems (TBCs) applied to hollow cylindrical specimens are presented in this work. The Electron Beam Physical Vapor Deposition coated specimens with internal cooling were designed to achieve realistic temperature gradients over the TBC coated material such as that occurring in the turbine blades of aeroengines. Effects of the circular cross section on the x-ray diffraction (XRD) measurements in the various layers, including the thermally grown oxide, are investigated using high-energy synchrotron x-rays. Multiple approaches for beam penetration including collection, tangential, and normal to the layers, along with variations in collection parameters are compared for their ability to attain high-resolution XRD data from the internal layers. This study displays the ability to monitor in situ, the response of the internal layers within the TBC, while implementing a thermal gradient across the thickness of the coated sample. The thermal setup maintained coating surface temperatures in the range of operating conditions, while monitoring the substrate cooling, for a controlled thermal gradient. Through variation inmeasurement location and beam parameters, sufficient intensities are obtained from the internal layers which can be used for depth resolved strain measurements. Results are used to establish the various techniques for obtaining XRD measurements through multi-layered coating systems and their outcomes will pave the way towards goals in achieving realistic in situ testing of these coatings.

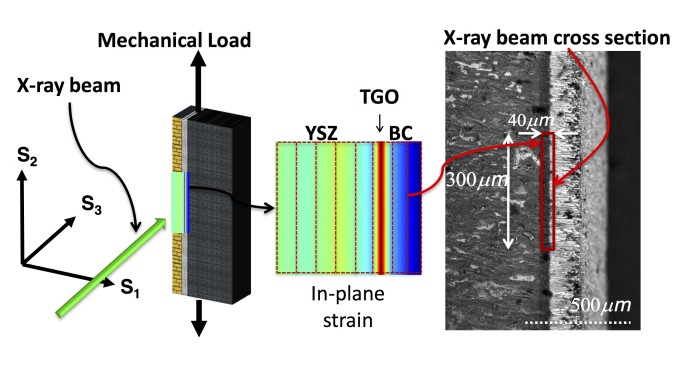

Role of Mechanical Loads in inducing in-cycle tensile stress in thermally grown oxide

Abstract

Experimental in situ synchrotron x-ray diffraction results tracking the strain behavior of the various layers during a cycle, under thermo-mechanical conditions are presented in this work. The quantitative strain measurements here show that the thermally grown oxide briefly experiences in-plane tensile stress with increased mechanical loading during ramp-up in the thermal cycle. These findings are the first in situ experimental observations of these strains under thermo-mechanical conditions, envisaged to serve as a catalyst for crack initiation. The depth resolved measurements of strain taken during applied thermal and mechanical load in this work are a significant step towards achieving realistic testing conditions.

Read our paper in Applied Physics Letters

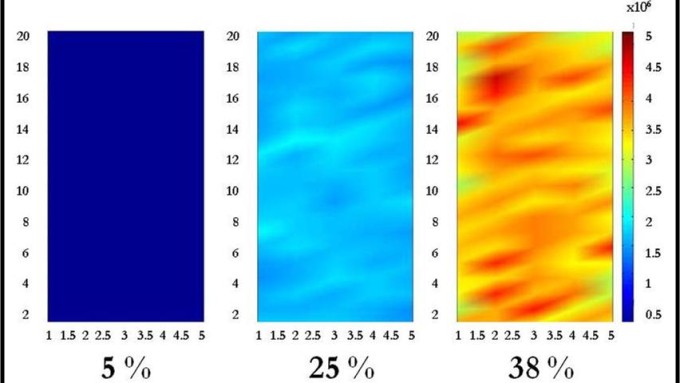

Characterization of particle dispersion and volume fraction in alumina-filled epoxy nano composites using photo-stimulated luminescence spectroscopy

Abstract

A novel method is presented to validate the dispersion of a-alumina nanoparticles within a polymer matrix, as well as to create a calibration for filler particle volume fraction identification. Using photo-stimulated luminescence spectroscopy (PSLS), spectral information from a-alumina-filled epoxy nanocomposites consisting of varying volume fraction quantities of alumina nanoparticles was collected and analyzed. Surface contour maps of each nanocomposite were created by comparing integrated intensity data from the R1 curve of a-alumina throughout each specimen. These maps show satisfactory dispersion of alumina in the 5 and 25% volume fraction composites, whereas agglomerations were detected in various regions of the 38% nanocomposite, establishing the capability of this method to characterize photo-luminescent particle dispersion. This new approach also provides high spatial resolution, which can be used to determine the exact locations of voids, inclusions and/or agglomerations, while also predicting the volume percentage of photo-luminescent particle content within a specimen, lending itself as a quality control method in the manufacturing of these composites.

Read the full paper at http://www.nature.com/pj/journal/v43/n11/full/pj201182a.html

Stress-sensing nanomaterial

Read our paper in Nanoletters

Abstract

Calibration of high spatial resolution stress-sensing alumina-epoxy nanomaterials is presented. The piezospectroscopic property of luminescent chromium-doped alumina nanoparticles embedded as “nano-sensors” in epoxy-based materials is the basis for the stress sensing capabilities. The stress-optical properties are determined as piezopectroscopic coefficients in compression experiments for nanomaterials containing varying volume fractions of alumina nanoparticles. An increasing stress-sensitivity was demonstrated with higher volume fractions. Thermal variations were shown to have negligible effects on the stress sensing property. The development of this material sensing system will enable quantitative measurement and non-invasive monitoring of stress distributions within a polymer system applied as adhesives or as coatings on a substrate under loading conditions.