Albert Manero wins Fulbright Fellowship to conduct doctoral research at DLR in Cologne, Germany

Monthly Archives November 2020

Lab Member Jose Mayi-Rivas Presented at the MS&T 2020 Conference

We are excited to announce that lab member Jose Mayi-Rivas presented his work as an invited speaker at the virtual MS&T 2020 conference, held earlier this month. In this study, a novel modeling method that enables fast predictions on residual stresses which depend on additive manufacturing parameters was showcased. The potential benefits of this modeling suite are tremendous as they would allow optimization of manufacturing processes, providing significant means for the improvement of mechanical designs of additively manufactured components. The talk was given in the symposium: Additive Manufacturing Modeling and Simulation: AM Materials, Processes, and Mechanics — Additive Manufacturing Modeling and Simulation – Residual Stress, Fatigue Property, and Thermal Property. Aside from his research in our lab, Jose is a Design and Analysis Engineer at NASA at Kennedy Space Center. Jose benefits from this industry viewpoint to further develop attractive modeling solutions in this research that can satisfy current and future industry challenges in this field.

Lab Member Quentin Fouliard Presented at the 2020 University Turbine Systems Research Project Review Meeting

We are excited to announce that our post–doctoral researcher, Quentin Fouliard, has presented recent outcomes and progress on our project funded by the Department of Energy named “In-situ Optical Monitoring of Operating Gas Turbine Blade Coatings Under Extreme Environments” at the 2020 University Turbine Systems Research Project Review Meeting, held on November 19. This presentation provided updates on the project tasks and showcased some of the accomplishments, including this year’s publications on the phosphor thermometry instrumentation and on thermal barrier coating damage monitoring.

Our Team Manufactured Thermal Barrier Coatings for Wireless Dielectric Sensing at FIT

Last week, lab members Quentin Fouliard and Johnathan Hernandez went to the Center for Advanced Coatings at the Applied Research Laboratory of the Florida Institute of Technology (FIT) in Melbourne, Florida. Our team manufactured thermal barrier coating configurations via air plasma spray that will allow to advance wireless dielectric measurements for non-contact temperature monitoring inside gas turbine engines. This novel approach is a joint effort between UCF faculty including our group and the research firm CREARE, and funded by STTR DoE. During thermal spray deposition, substrate temperature was recorded using infrared cameras and these results will support modeling efforts for stress predictions in as-deposited coatings.

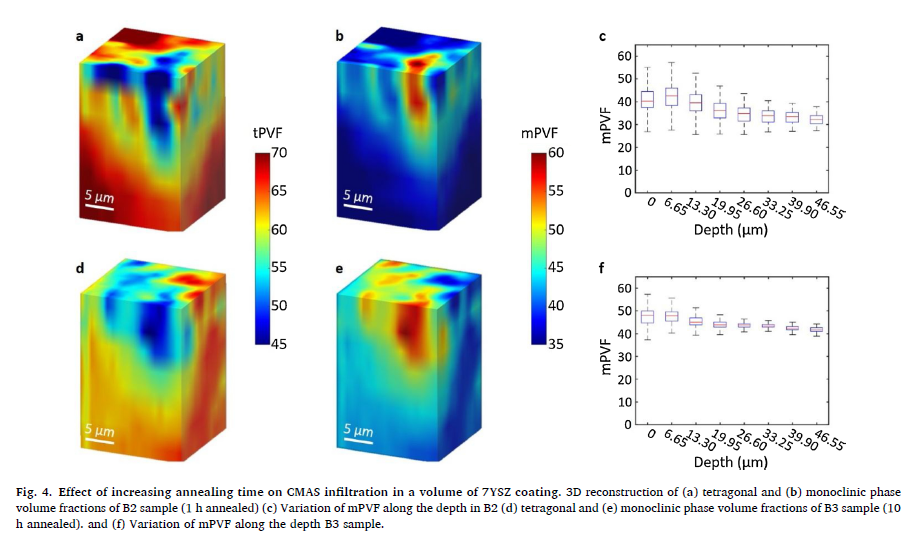

Paper on Thermochemical Evolution of CMAS-Infiltrated TBCs Published to Journal of the European Ceramic Society

We are pleased to announce that our paper titled “Detrimental effects of sand ingression in jet engine ceramic coatings captured with Raman-based 3D rendering”, by lab member Zachary Stein, has been published in the Journal of the European Ceramic Society. The work presented in this paper was done in collaboration with the German Aerospace Center (DLR) through the NSF International Research Experience for Students (IRES) program. The results were obtained using 3D confocal Raman spectroscopy to map the thermochemical evolution of monoclinic phase volume fraction in standard EB-PVD TBC coatings infiltrated with CMAS. This provided a method for quantitatively and non-destructively characterizing the degradation of coatings as a result of CMAS infiltration.